We can help you with your heat transfer problems. Dimpled plates are simple solutions for cooling or heating your process (reactor, pressure vessels, destilation columns, ect). We can calculate the necessary heat exchange surfaces, the spacing between plates and other dimensional parameters for each application.

Thanks to more then 30 years experience in the heat transfer technology, we can guarantee our heating and cooling processes as well as our mechanical design.

Thanks to more then 30 years experience in the heat transfer technology, we can guarantee our heating and cooling processes as well as our mechanical design.

To get a better mechanical strength (allowable pressures and thermal shocks), our exchange plates are welded using CNC laser technology.

Range of pressure and temperature

Common used thermal media

We deliver complete solutions instead of just products. For example the following problem.

Our customer had a problem with a gas reducing station. The valve couldn’t handle the designed capacity. So they needed an other one which could handle the needed capacity for the gas reducing station.

However, our customer had two specific questions:

Whether we could supply the complete gas reducing station.

If we could replace the complete gas reducing station within 2 days.

The pictures show the three situations:

|

|

|

| 1. Old situation | 2. Complete build out | 3. New situation |

With our experience and engineering capabilities we will always deliver a reliable solution that will perform to your expectations.

We are happy to introduce the supply of industrial plastic/composite solutions. This is in line with the vision of EMS supplying customers with tailor-made industrial equipment.

What problems do we solve?

We can divide the product range into 3 groups:

Odor control solutions using technologies such as bio-filters, biotrickling, chemical scrubbers, activated carbon, RTO and advanced adsorptions.

Storing with vertical tanks, cisterns, reactors, decanter, rectangular barrels, underground tanks.

Pumps for high performance and maximum reliability. Up to 1500 m³/h and suitable for pumping corrosive products with fumes and solids, including high models that specifically permit dry runs.

Products are supplied after we have done problem analysis and process- and mechanical design.

With our experience and engineering capabilities we will always deliver a reliable solution that will perform to your expectations.

We are happy to announce that EMS Energy Management Systems b.v. is now the official representative for PBM Valves Solutions in the Netherlands. With our combined strength, we will provide the best solutions to the Dutch market.

Interested? Please contact our sales engineers for more information at info@emsvalves.com.

PBM valves offer the convenience of standard features with the option of customizing for a specific process. Most PBM valves incorporate PBM’s Adjust-O-Seal® design and many include the True-Bore® port design. Only PBM has the ability to provide Clean-In-Place / Steam-In-Place capability without process interruption. These are just a few of the innovations that help reduce processing costs and improve efficiency for our customers.

Customer:

Process plant

Application:

Gas Flow Control

Problem:

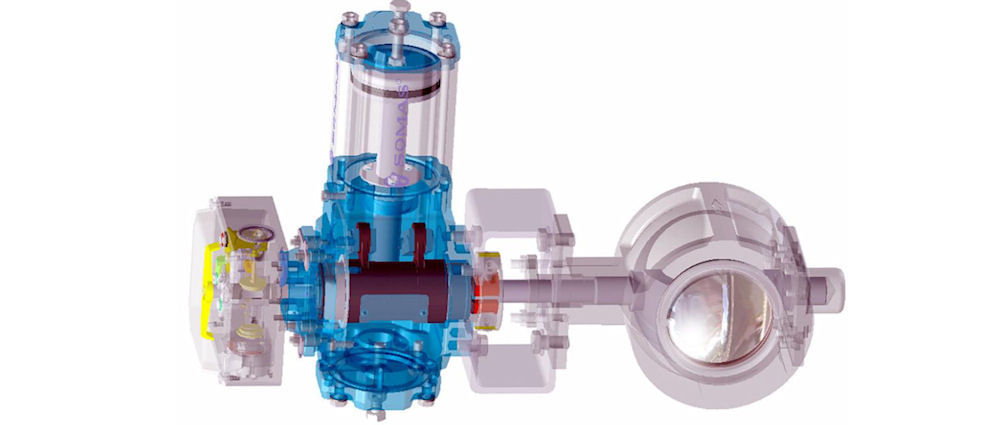

Accurate Gas Flow Control in this customers process plant was required to produce desired quality of products. The challenging requirements for the Gas Flow Control valve were a combination of high turndown with minimal pressure drop, good controllability , low noise, gas tight shutoff, high accuracy & reliability.

Solution:

We started with analysing the customers problems and understanding the process requirements. This is a key factor in getting the right fit for your application. The design of the supplied segmented Ball Valve offers good characteristics that match the process of our customer. This was achieved by selecting the proper flow capacity with good controllability over the entire flow range. Seat material was selected for optimum tightness and less wearing for easy maintenance and less need for spares. We were also able to offer the segmented ball valve at very competitive price levels and short lead time of only 4 weeks.

If you have a similar application, do not hesitate to contact us for information!

Customer:

Combined Cycle Power Plant.

Application:

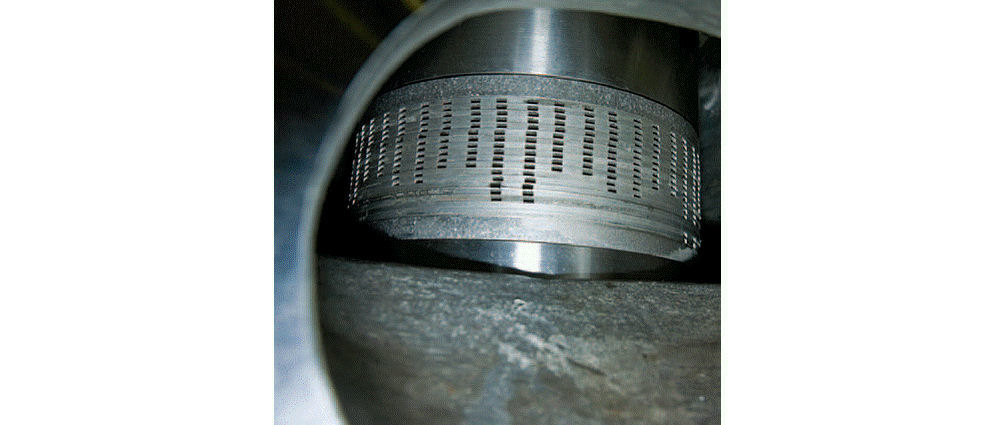

Low Noise Steam Pressure Reducing Valve.

Problem:

Accurate Steam Flow Control in this Combined Cycle Power Plant was required for flexible duty. The challenging requirements for the Steam Control valve were a combination of high turndown with minimal pressure drop, good controllability over entire operating range, low noise generation, tight shutoff, high accuracy & reliability.

Solution:

Low Noise Globe Control Valve with characterized disk stack ranging 4 to 20 stages of pressure reduction in the severe service trim. Allowing good controllability of both low and high flowing capacity.

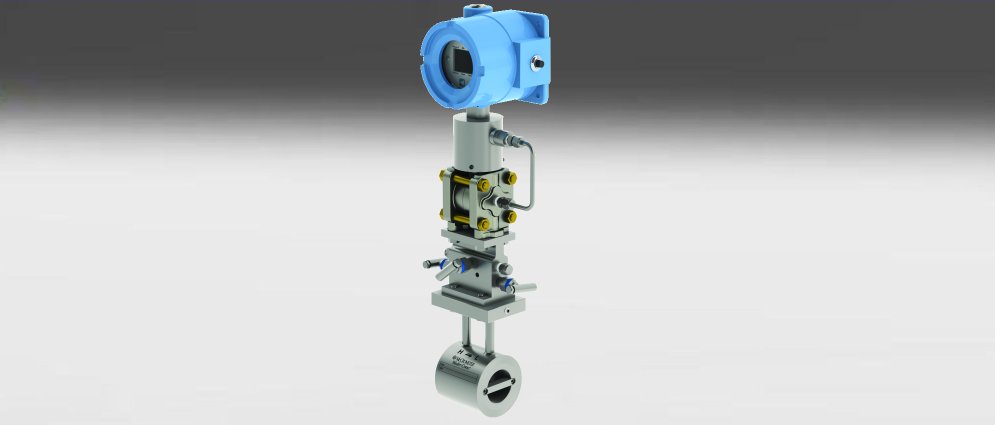

Customer:

SKID Manufacturer

Application:

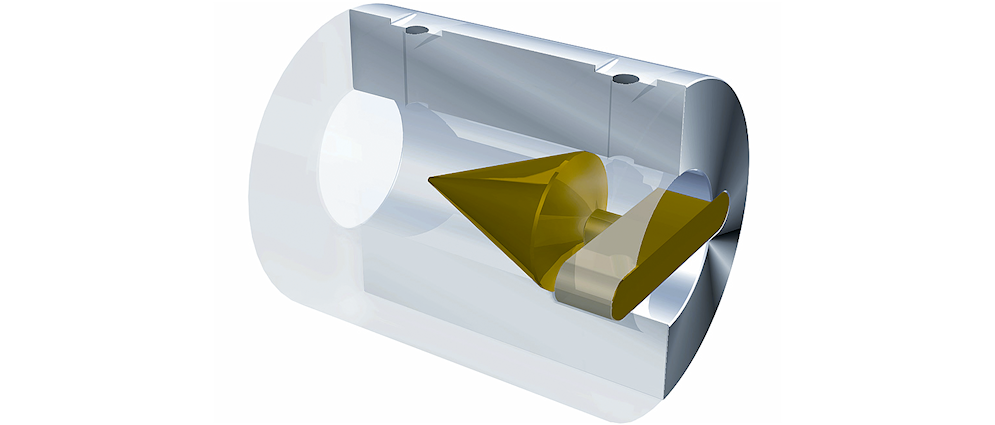

Gas Flowmeter

Problem:

The limited foot print of the skid caused problems with conventional flow meters requiring large straight lengths of pipe up- and downstream for meter accuracy. Also the high required rangeability (20:1) and very limited acceptable pressure loss in the process caused engineering problems.

Solution:

The V-Cone flowmeter combines high rangeability with both very limited permanent pressure loss of just 3 mbar and if required also a high accuracy of 0.5%.

The fact that it did not require any straight length of pipe to achieve this makes it an excellent solution in process skids.

If you have a similar application, do not hesitate to contact us for information!

Customer:

Compressor Station

Application:

Anti-Surge Flowmeter

Problem:

To prevent the compressor from surging, a flowmetering device is placed in the compressor piping to monitor the gas flow through the compressor. For optimum compressor control this flowmeter has to always provide a precise, stable and reliable flow signal.

Solution:

McCrometer’s patented V-Cone® Flowmeter’s unique design offers an advanced, differential pressure flow technology that acts as its own flow conditioner, fully conditioning and mixing the flow prior to measurement. The result is a low amplitude, high frequency signal with little “signal bounce.” Readings are always precise and reliable, including low pressure flow situations. The V-Cone offers an almost instantaneous response time and large turndown, which allows the compressor control to be fine tuned. This provides better results when using prediction control software and also helps simplify compressor installation construction due to the flowmeter’s inherent conditioning action. Another advantage is it’s outstanding performance without the upstream or downstream piping required by other flowmeters. This results in significant space and weight savings. For retrofit purposes, the V-Cone is simple to install. The V-Cone provides an accuracy from ±0.5% of rate and a repeatability of ±0.1%. It comes in sizes from 1/2 inch to over 120 inches. It handles flow turndowns up to 20:1. High pressure meters are available. Corrosion resistant models in most materials are also available.

Customer:

Process plant

Application:

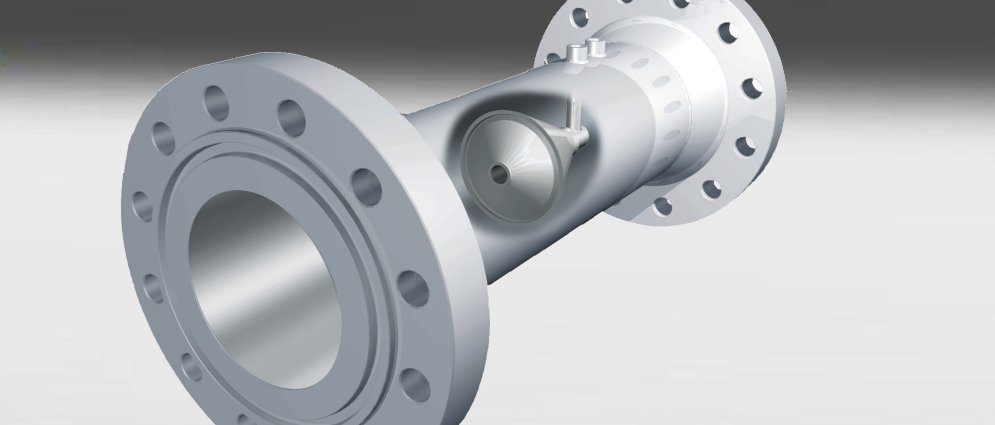

Steam Temperature Control

Problem:

Accurate Steam Temperature Control in this customers process plant was required to produce desired quality of products. The challenging requirements for this Desuperheater were a combination of high turndown with minimal pressure drop, minimal available space, high accuracy & reliability.

Solution:

The design of the supplied Desuperheater offers good characteristics that match the process of our customer. This was achieved by selecting the proper spring-loaded spray nozzle and characterized capacity over cooling pressure in combination with high performance spray water valve for cooling pressure control. As a standard service EMS advises with calculations to help optimize on piping layout. This is a key factor in getting the right fit for your application.

If you have a similar application, do not hesitate to contact us for information!

Customer:

Process plant.

Application:

Compact Process Flowmeter.

Problem:

The stringent requirements for this Flowmeter were combination of high turndown with minimal pressure drop, minimal available space, high accuracy & reliability.

Solution:

The Wafer Cones unique design offers an advanced, differential pressure flow technology that acts as its own flow conditioner, fully conditioning and mixing the flow prior to measurement. The result is a low amplitude, high frequency signal with little “signal bounce.” Readings are always precise and reliable, including in low pressure flow situations. The V-Cone offers an almost instantaneous response time and large turndown, which allows process settings to be more fine tuned for better process control. Another advantage is it’s outstanding performance without the upstream or downstream piping as required by other flowmeters. This results in significant space and weight savings. For retrofit purposes, the V-Cone is simple to install requiring only very limited installation space. It is also not sensitive to dirt or fouling. Corrosion resistant models in most materials are available.

If you have a similar application, do not hesitate to contact us for information!