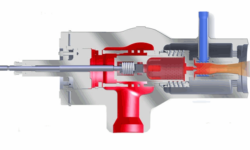

EMS can revise and repair your valuable control valves. After this process we will guarantee the valve as new including all certification/documentation. Below an example of the revision of a valve.

|

|

||||||||||||||||||||||

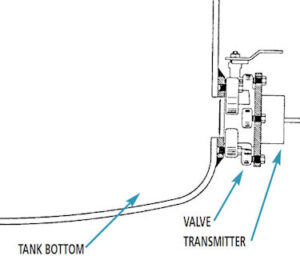

EMS is a specialist in solutions for tank bottom valves. Especially in difficult situations like high pressure, high temperature and difficult media. We understand how important it is that your tank bottom valve has no failure or leakage. This will result in downtime and costs.

Solving problems

How do we solve these problems?

For example with these 2 valves:

|

|

All valves can be manual or actuated.

EMS solved several problems regarding the reliability and accuracy of sampling. The best solution is an Automatic Insertion Probe Regulator. The Probe regulator is designed to provide an analyzer with a sample stream at an output pressure adequate for downstream instrumentation.

All our Automatic Insertion Probe Regulators are designed according to and comply with API 14.1, GPA 2166 and ISO 10715.

|

|

What are the benefits?

1. Convenience – Ease of operation

Insert and retract the probe at full pipeline pressure simply by turning four valves. NO EXTERNAL SOURCE REQUIRED.

2. Regulation – The process

The sample stream is regulated at the probe tip to minimize line pack and sample retention, allowing the regulated sample stream to reach the analyzer more quickly.

3. Precision – Diaphragm design

The diaphragm design in the regulator optimizes low-pressure output sensitivity.

The Automatic Insertion Probe Regulators are available from 0-12” to 0-42” insertion length, pipeline connection NPT (¾”, 1” 1½” and 2”), Flanged (1” to 3”, rating 120 to 2500). Materials including 316 SS, Titanium, Hastelloy and Inconel. The probes are approved and comply with government regulation.

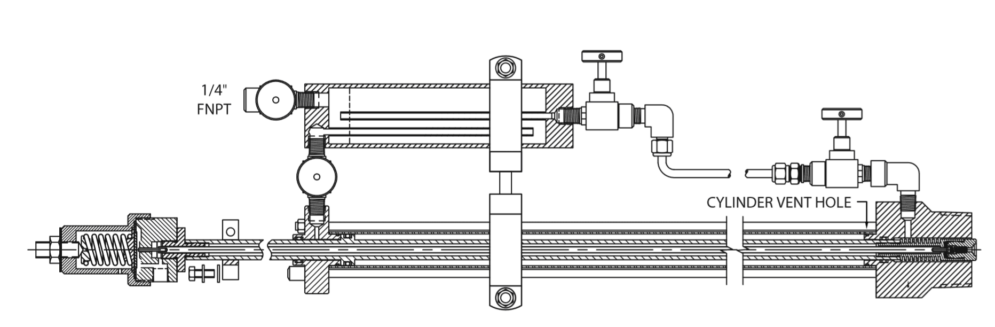

EMS solved several problems regarding the reliability and accuracy of sampling. The best solutions is a constant pressure cylinder. Recognized and utilized for their outstanding transport of two-phase gas samples, natural gas and specialty gas products. Besides maintaining samples at pipeline pressure, the cylinders provide superior vortex mixing action, all in a compact, manageable and easy to use package.

All of our constant pressure cylinders are designed with a standard 4-1 safety factor, unequaled in the industry and give years of dependable service and quality results.

How does it work?

The cylinder is pressured with an inert gas supply. By letting the gas push against the piston, the sample is taken at full line pressure from start to finish. In the laboratory, a gas supply could be connected to the pre-charge side equal to the pipeline pressure. As the sample gas is injected into the chromatograph, the piston is being pushed by the pre-charge gas. The gas composition is not altered as a result of pressure reduction. The cylinder can be stored or sent for conformation to another laboratory, it will give repeatable results, because the condition of the gas is maintained by the constant pressure cylinder. The cylinder is equipped with valves, safety reliefs and gauges on both ends so the pressure can be controlled at all times on both sides.

This procedure has proven to give extreme accuracy in both spot sampling as well as in automatic sampling systems. The constant pressure cylinder maintains the integrity of the sample within ½ BTU of the pipeline gas. No other design comes that close!

The constant pressure cylinders are available from 150 psi to 15.000 psi working pressure, volumes from 10 ml up to 35 liter. Materials including 316 SS, Titanium, Hastelloy and Inconel. The cylinders are approved and comply with government regulation. Sulfinert and chembar coatings are available for high sulphur applications.

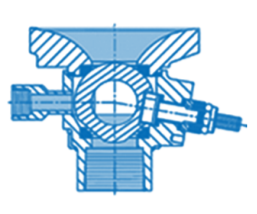

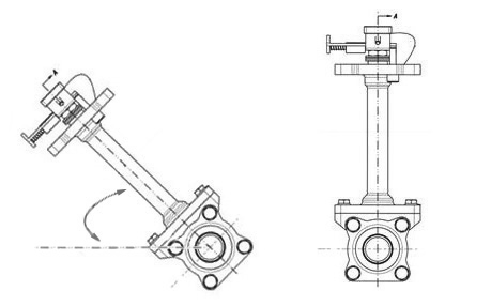

We want to introduce our cryogenic ball valve.

|

|

| Figure 1: Best orientation for operation Cryogenic Valve (45 deg) | Figure 2: Isometric view |

What makes it work?

An extended bonnet with an upper set of live loaded stem packing. As metal shrinks, it keeps pressure on seals as temperature goes through cooling and heating cycles. Vented ball allows explosive gas expansion to vent upstream.

Features:

EMS can solve problems in ball valves like:

This is solved as result of up and down-stream sealing of the ball valve. In combination with the several features like:

We will deliver a ball valve which has less maintenance, less downtime and is safe and reliable.

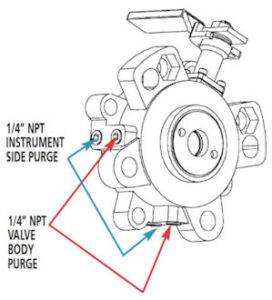

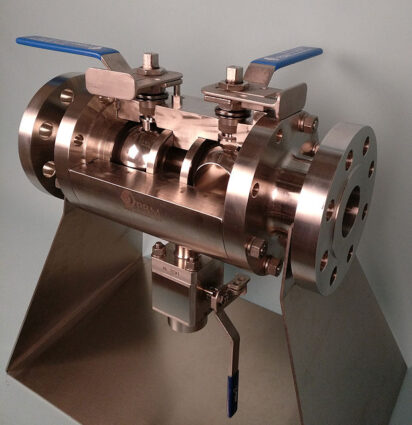

We can supply you a Transmitter Isolation Valve (TIV) which has:

How?

We have a TIV ball valve type, which has less face to face length (figure 2) then a normal ANSI style valve. With the “flush and clean” feature. Flush and clean is applied around the ball and between the transmitter and the ball (figure 1). The TIV can easily be mounted on your transmitter and tank connection.

|

|

|

| Figure 1: Flush and clean ports | Figure 2: Small face-to-face length | Figure 3: Isometric view |

With our experience and engineering capabilities we will always deliver a reliable solution that will perform to your expectations.

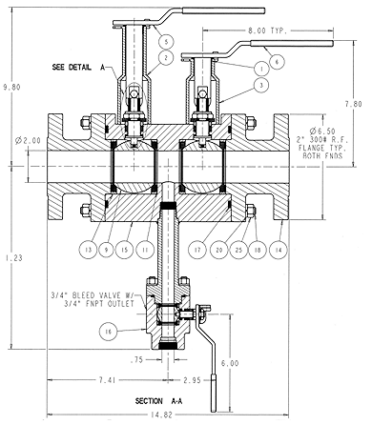

Double block and bleed valves are perfect in applications when you need a safe system. The pipeline can be depressurized and the operator will not get in contact with dangerous medium and high pressures.

|

|

| Figure 1: Sample valve | Figure 2: Detail drawing |

EMS double block and bleed valve provide true double positive isolation:

This configuration provides the best technology for the most severe isolation services. We can make the valve complete custom to your requirements (including extended spindles for insulation, special end connection and more).

With our experience and engineering capabilities we will always deliver a reliable solution that will perform to your expectations.

Our customized maintenance portfolio:

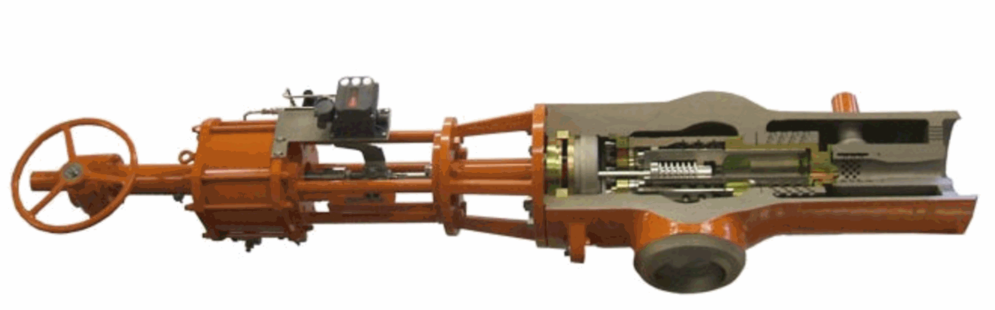

We want to introduce the DSCV-SA (Direct Steam Converting Valve – Steam Atomization). The DSCV-SA is a world leading steam conditioning valve specifically designed for the most arduous applications such as steam turbine bypass systems, either open or closed cycle, continuous steam letdown stations and CHP plants. These valves form a critical part of the safe and efficient operation of all power stations and steam distribution systems.

The DSCV-SA is an angle style construction with the steam inlet through the branch connection and the steam outlet through the in-line connection. The connections can be either flanged or butt welded depending upon the customer preference. The valve can be provided up to ANSI 4500# rating.

The valve can be fitted with single stage HUSH, multi stage HUSH or Copes-Vulcan RAVEN trim technology depending upon the pressure drop and to meet the requirements of specific noise levels. The valve is provided with high pressure balancing, single seat trim construction utilising a tandem trim pilot operated concept ensuring tight and repeatable class V shutoff per ANSI/FCI 70-2

With our experience and engineering capabilities we will always deliver a reliable solution that will perform to your expectations.