Customer:

Research Laboratory

Application

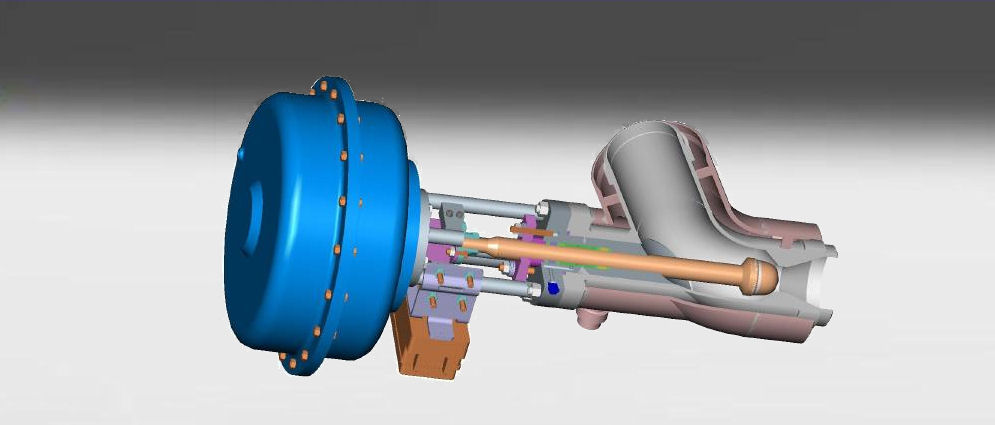

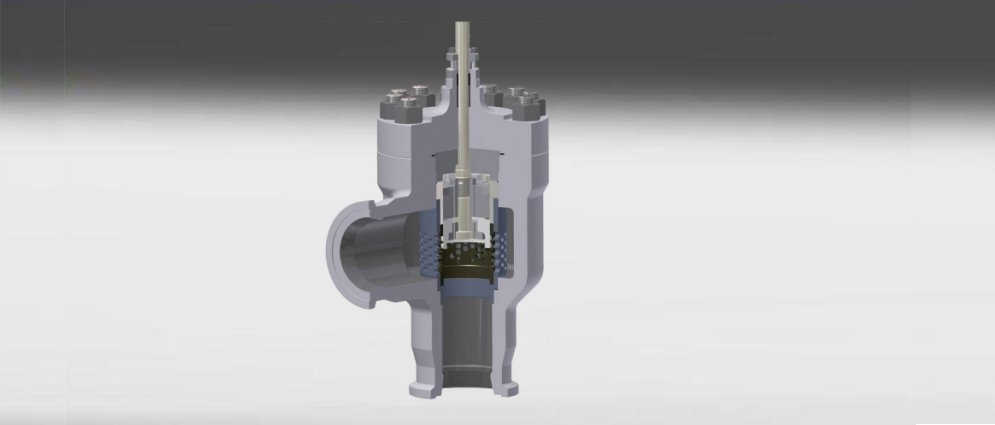

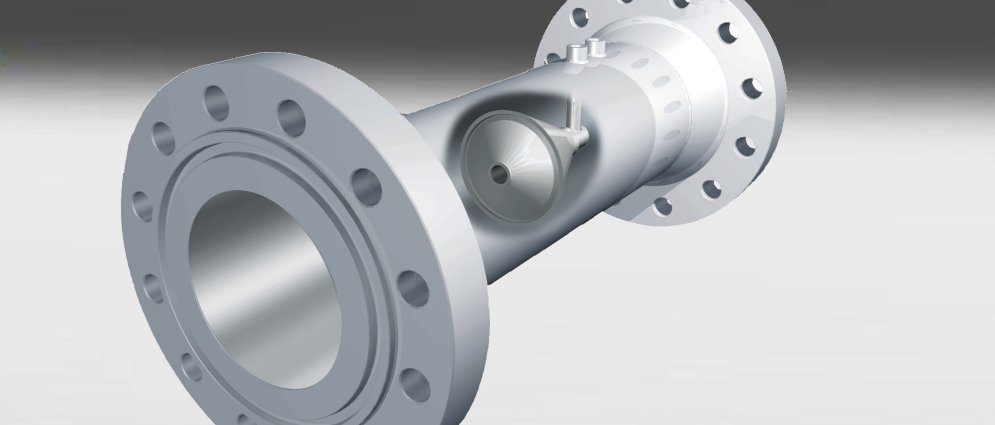

Fluidized Catalyst Control Valve

Problem:

The Combination of high temperatures, high velocities and abrasiveness of Catalyst Powder. Minimum required lifetime of 1000 operating hours without maintenance. Guaranteed Leak tightness of valve.

Solution:

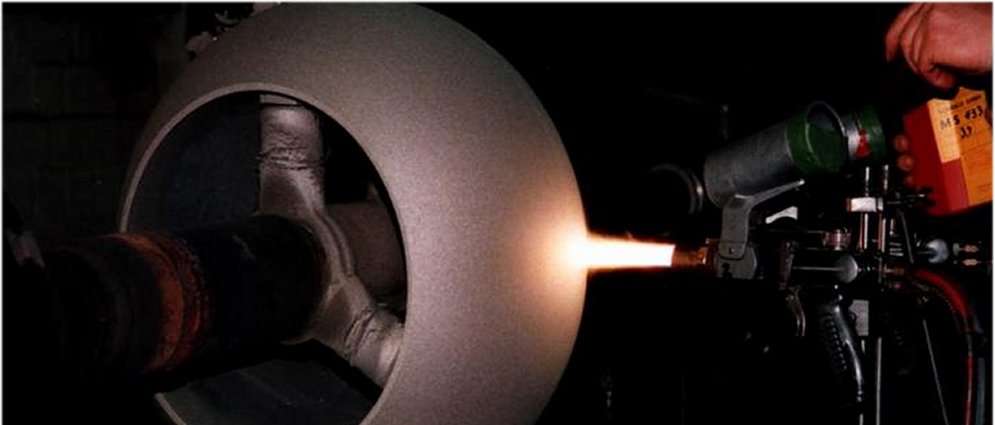

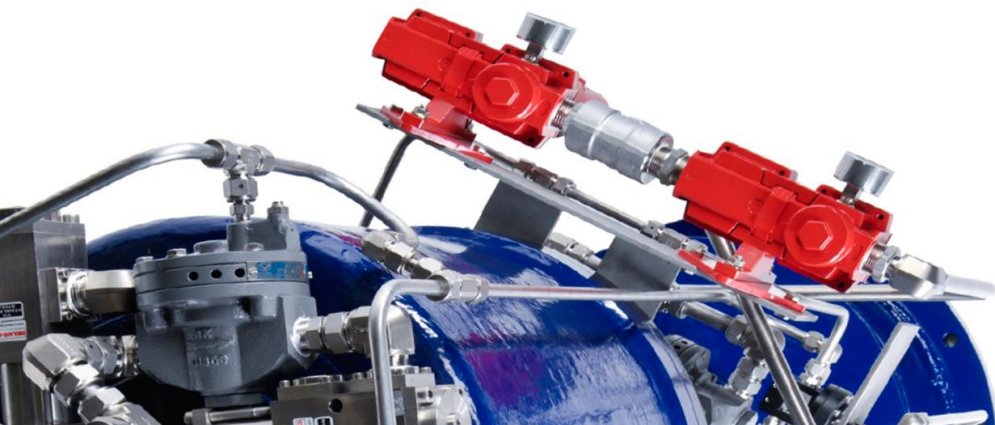

Guichon Type 607R Needle Style Control Valve. Welded design and construction, body in AISI 304H Class 300# Metal to Metal seating with plug lowering into angle valve ( 60 degrees) Trim in AISI 304H + Full Stellited + Kolsterized Single acting actuator with smart positioner.

We have launched our new website! Please browse through our website and see what we can do you. If you need any help, feel free to contact us.

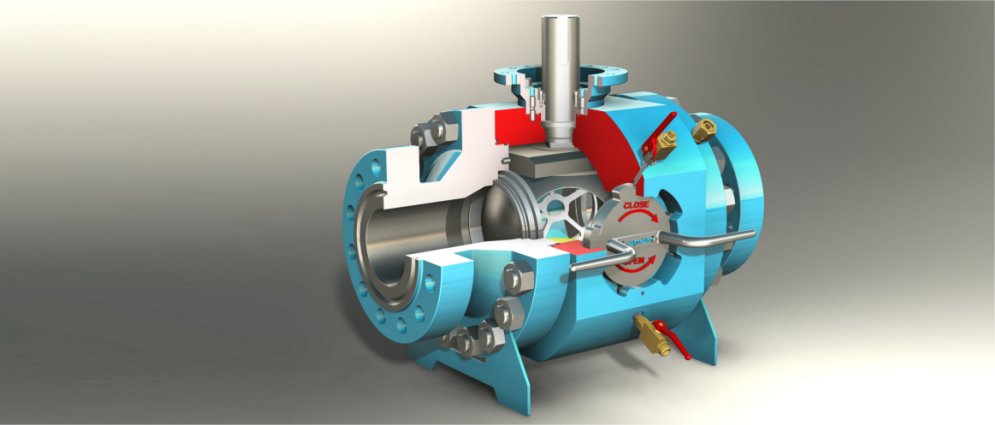

Within the process of a plant Control Valves are the final acting elements to reach desired conditions. They are used to control pressure, temperature, level, or flow in a pipeline system. EMS offers a complete range of control valves:

Applications range from general service to cryogenic, high temperature, or severe service valves. We provide solutions for applications in anti-surge control, anti-cavitation and low noise requirements. We offer you high-grade solutions at very competitive price settings.

EMS can perform both preventive and corrective maintenance work for you. We can also help to evaluate and optimize your maintenance strategy to get a right balance:

EMS has information on upgrades, diagnostics and best practices as well as available tools.

The reliability of an installation against the “lowest total cost of ownership” (TCO) is determined by adequate spares management. EMS will support you by providing you with original spares and advice on what improvements/upgrades are now available from the original manufacturer. This assures safety of plant personnel, compliance with CE, PED, ATEX regulations, quality and reliability, and keeps you in compliance with engineering rules. This is the only way to avoid problems with safety, regulations, incompatibility of parts and availability.

Research is vital to our understanding of industry applications and it is the first step in providing a good solution. Experience combined with technical expertise in fluid mechanics makes the difference in this area. The use of High-performance design tools complements it. Together with our partners we are able to bring you personalized innovative solution for the most divers and complex process problems.

EMS offers flexibility in flow metering applications. With self-conditioning no-moving parts DP technology, the V-Cone® Flow Meter supports the most challenging flow applications throughout industries. The V-Cone offers high accuracy, wide rangeability, low maintenance and long-life service. All this while undergoing only a marginal pressure drop in the process. Key Features / Benefits

For example: We successfully installed flow measurements for cryogenic applications where they previously remained unmeasured. We have solved problems in LNG applications for gas liquefaction trains and storage tanks.

Retrofitting existing valves and instruments can be a good way of making these components suitable for (modified) process circumstances; it offers a cost-effective and time-efficient approach to preventing or resolving problems. EMS will also keep track of these changes and inform the original manufacturer to update their system. This is the only way to ensure reliable parts support in the future.

EMS helps customers to optimize effective spares management by using interchangeability records. We have also developed tools to help customers gain insight into actual spares usage and identify room for improvement (also see spare management).

Besides our own experience and knowledge we work with the industry specialists to make sure the most economic solution is provided. This way we are able to optimize between the current best practices, state of the art solutions and revolutionary new designs. Ultimately this helps advancing the competitive edge of your company.